On any construction site, especially in South Africa, time is money, as the old adage goes, and your cement mixer is right at the core of your productivity. When it is running smoothly, when the batching process is efficient, placement is continuous, and your team stays on deadline. However, when these things aren’t running smoothly, you lose precious time, waste fuel, and run the risk of having your concrete set before it is even placed.

Now, most contractors have seen this happen, clogged drums, later water top-ups, or even a crew member running awry, back and forth for materials while the rest of the team waits. These kinds of delays not only cost you minutes but also cost you profit down the line. Basically, poorly timed batches can lead to slump loss, cold joints, or even inconsistent strength, which will lead to inevitable callbacks and reworks.

The Goal Is More Output With Less Waste

Maximising your efficiency on site isn’t simply about operating your cement mixer at a faster pace; it’s about working more intelligently. This involves conducting thorough equipment inspections before mixing begins, carefully planning your loadout and assigning crew roles to prevent any bottlenecks, staging materials so that every batch remains consistent, and maintaining your cement mixer to avoid unnecessary and preventable breakdowns.

A Mini Scenario: Two Crews, Two Outcomes

Say for example Crew A takes only ten minutes between batches because they have to fetch sand then refuel midpour, the concrete stiffens, the footing shows cold joints, and the client calls them back to fix cracks. On the other hand, Crew B staged their materials beforehand, they did prechecks on the mixer, and assigned their site roles beforehand, they finished faster, achieving a monolithic footing and a satisfied client.

In this BS Power guide, we’ll co er everything, the practical, job-tested methods to boose your efficiency with cement mixers, which will help you avoid expensive downtime, and achieve the best results with every pour.

BS Power’s Pre-Start Checklist For Cement Mixers

A smooth, beautiful pour starts long before your first bag of cement even hits the drum. Taking as little as ten minutes to properly check your cement mixer at the start of the workday can save you hours of possible downtime, and literally hundreds, if not thousands, of rands in the long term.

Your Cement Mixer’s Engine Health & Fuel System

Whether you’re operating a Honda GX160-powered 360L mixer or a 400L Baumax, the engine is truly the backbone of your cement mixing setup. Before starting the machine, it’s crucial to check the oil level, as running on low oil can cause the mixer to stall or, in the worst case, result in engine seizure.

Take the time to closely inspect the fuel filters and spark plugs for any signs of clogging or fouling, since dusty construction sites often lead to dirty fuel problems. For diesel-powered mixers, it’s also important to bleed any air from the fuel lines after transporting the mixer and to check the fuel tank for any signs of water contamination, both of which can seriously affect performance.

The Drum & Blades

Maintaining a clean and well-kept cement mixer drum is essential for ensuring every batch is mixed consistently. It is important to thoroughly inspect the mixer’s blades, as any that are bent or worn out can cause “dead zones” where raw materials are not properly blended.

Additionally, all hardened concrete from previous workdays should be completely removed, as even a small amount of set material can reduce the drum’s capacity and negatively affect your mixing ratios. Before starting, it is also good practice to spin the empty drum and listen for any unusual noises, since grinding sounds may point to worn bearings or problems with chain tension.

Stability And Positioning Of Your Cement Mixer

It is essential to place your cement mixer on stable, level ground near the pouring area to ensure efficiency and safety during the job. Avoid setting it up on soft soil or surfaces where the legs might sink while pouring, as this can disrupt your work and compromise the quality of the mix.

Whenever possible, position the mixer in a shaded area to help keep the aggregates cool, which helps maintain the desired slump and prevents premature stiffening of the concrete. Additionally, make sure there is a straightforward and unobstructed haul path leading from the mixer directly to the formwork, allowing for smooth and uninterrupted transport of the concrete.

How To Optimise Your Setup: The Layout, Crew Roles And Site Preparation

Right, so once your cement mixer is ready to go, your next step would be to set up the site so that you’re batching and placement flow smoothly. Having a properly planned-out layout can shave off minutes on every batch.

Position Your Mixer For Shade And Wind Protection

The sun and wind are silent killers of site productivity, in fact, direct sunlight can heat up your drum and the aggregates, which cut working time by as much as 30% on a sweltering hot SA day.

As mentioned above, try to shade your mixer by placing it under either a shade net, tarp, or tree cover to keep the temperature of your concrete stable. You can also use ply boards or shade cloth as wind breaks near the pour site to prevent premature surface drying.

How To Stage Water And Other Materials

Ask any contractor, nothing, we mean nothing, slows down a pour like a missing wheelbarrow of sand. We recommend pre-staging all your aggregates and cement within arm’s reach of the loader. Also, store your cement bags off the ground and under shaded cover to prevent any moisture contamination. Lastly, make sure your site has a reliable water supply. Simply fill a header tank or drums before you start so that your crew doesn’t waste time waiting on municipal pressure while pouring.

Set Up Clear Haul Pathways

Your wheelbarrow runs need to be as short and smooth as possible, so make sure you level and compact your haul path or lay down some boards to avoid spillage and work from the farthest point back toward the cement mixer to prevent crossing over fresh concrete.

Assigning Crew Roles

Before you begin, it’s essential to assign specific roles to your crew. The Loader is responsible for accurately measuring and loading all aggregates and cement into the mixer, while the Water Man oversees the precise amount of water added, using either buckets or flow meters to control dosage.

Meanwhile, the Runner ensures that wheelbarrows are continuously moving between the mixer and the pour point to maintain an efficient workflow. Finally, the Placer or Finisher takes charge of levelling and vibrating all the concrete on site, ensuring a smooth and consistent finish for the entire job.

How To Batch Plan To Reduce Downtime & Waste

Even if you have the best setup, poor planning can wreck your crew’s productivity. The term “batch planning” refers to matching the output of your mixer and your crew’s ability to place and finish before the mix hardens. Getting this wrong will result in your crew either waiting on concrete or rushing to place before the batches stiffen.

Knowing Your Cement Mixer’s True Output

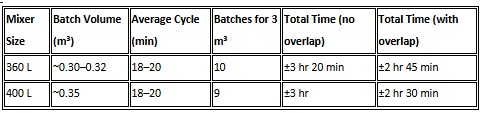

Nominal capacity is not the same as effective output. For instance, a 400 L cement mixer produces around 0.35 m³ per batch. Say perhaps each cycle takes 20 minutes from loading to discharge, which equates to around m³ per hour, but if you were to overlap your cycles, you can drastically raise your effective output:

Overlapping To Maintain Flow

We recommend starting on your next batch before the last barrowload of the previous one has been placed. This will keep your concrete flowing continuously and help you avoid cold joints.

How To Adjust For Weather

During the hotter summer months, you may find that your working time decreases significantly, sometimes by as much as 30 to 50 per cent. If you notice the concrete slump reducing before you can place your next load, it’s advisable to make each batch a bit smaller, allowing them to be processed more quickly through each cycle.

Additionally, consider bringing in an extra crew member or two, such as a fourth or fifth person, to help maintain a continuous placement process. This added support not only keeps the workflow steady but also frees up valuable time for the crucial finishing and curing stages.

Always Plan Before You Pour

Planning is everything, and this is no different in the construction industry, we suggested planning out your batch plan before you start, and this includes the number of batches needed, the estimated time per cycle, and your crew assignments. Having a visible plan will help keep everyone on the team aligned and will also prevent mid-pour confusion.

BS Power’s Mix Design Tweaks

Achieving efficiency won’t stem solely from batching faster, it will come from producing a mix that’s easy to work with, that doesn’t compromise on strength. To get to this level of mix efficiency, you need to pay close attention to your aggregates, water, and optional admixtures.

How To Control Water Like A Pro

It’s well known among construction workers that water is often the most misused component on site. Adding a little extra water may seem convenient, but it actually weakens the cement paste, reducing the concrete’s strength and making it more susceptible to shrinkage cracks. For accuracy, use buckets or a flow meter when measuring water. If you’re working with a 400 L mixer (about 0.35 m³ per batch), you’ll need roughly 60 to 65 litres for a 20 MPa mix.

Always remember to factor in the moisture already present in your aggregates, as damp sand can unintentionally increase your water content, so reduce the amount you add to keep your slump within the desired range. Finally, never add water after the initial mixing process; if a batch becomes too stiff, it’s best to discard it or use it only in non-structural areas.

Our Top Cement Mixers Built For Job Sites In SA

No matter how skilled your team is, it’s essential to have a cement mixer that matches their efficiency. At BS Power, we supply contractor-grade cement mixers specifically engineered to handle a consistent workload, day in and day out, even under the demanding conditions commonly found across South Africa.

For smaller pouring projects such as footings, garden walls, or patch slabs, the Honda GX160 Cement Mixer stands out as a compact and fuel-efficient choice. This model is particularly valued by small and medium enterprises thanks to Honda’s reputation for engines that start easily and deliver a long service life.

If your projects require a bit more capacity, the Baumax 400 L Cement Mixer is an excellent option. With its larger drum, it enables quicker completion of driveways, medium-sized slabs, and small commercial jobs, while its robust construction and cost-effectiveness continue to earn it praise among contractors.

All in all, both of these cement mixers have been designed with durability, easy maintenance, and increased productivity in mind, so your team can spend more time pouring and less time fixing.

If you’re ready for smoother pours, fewer delays, and a much happier clientele, getting the right cement mixer is your first step. Be sure to visit the BS Power webstore today to explore our full range of cement mixers and find the right model that matches your specific workload.